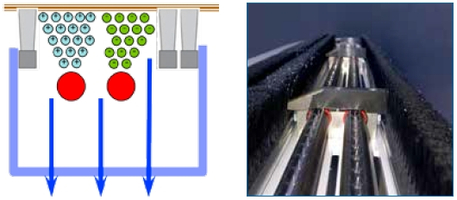

// How does our Ionization System work?

- A vacuum chamber is located beneath the fixed brushes and electrodes.

- The first set of brushes detach angel-hair and/or larger paper particles and these larger particles are then drawn away from the board by the vacuum chamber.

- The electrodes electronically ionize the Oxygen (0₂) and Nitrogen (N) atoms found in the air above, and are designed for press speeds up to 1000 ft. /min.

- While creating an ionic field above the electrodes, the polarity of the electrodes alternates at a frequency of 50 Hz, creating positive and negative ions, which neutralize the static charge of the dust particles.

- As the board passes through the ionization field, the no-longer statically charged dust particles can be loosened, detached by the second brush and drawn away by the vacuum chamber.

// How efficient is the system?

Efficiency of the system will depend on the process; plant cleanliness, the precision of the edge trimming and considering the type of boards being used. Nevertheless, a reasonable goal of 4000-5000 sheets/h, without stoppages caused by dust-related issues, is easily attained. The Return On Investment of our system would be between 18 – 24 months.

// What additional options are available?

- Depending on the machine in question, an automatic board thickness adjustment option is available

- For severe angel-hair problems, the addition of a front rotating brush is available.

- When a dust collecting system is not available, our Centrifugal Dust Collector can be installed

// On what machines can this system be installed?

This system can be installed on nearly every type of printer like Bobst, Bobst DRO, Bobst FFG, Gopfert, BGM, Emba, Celmacch, MHI, LMC and many more!