Duo-Technik’s ACS is also a machine integrated system which is able to make interim plate cleaning which takes only 6 minutes and a effective final plate deep cleaning that takes only two minutes. The printing machine has to be stopped during the cleaning process.

// What is the system used for?

The goal of the ACS system is not only to remove dust spots or dry ink but to deep clean the printing plates. This is especially recommended for long inline production runs. However the printing machine has to be stopped to do the cleaning. This is an interesting feature, since based on the actual ink condition, more or less ink will dry and accumulate on the printing plates and this is really difficult to remove with an in-production cleaning system.

What they receive:

- In-depth cleaning of all printing plates in 6 minutes

- The 3rd sheet after cleaning is commercial quality

- Quick final cleaning of wet printing plates in two minutes

- Final cleaning of the printing plates can take place during the set-up of a new job

- Metered make-up and controlled usage of soap for the cleaning cycle

- Printing plates are maintained in optimal condition

// How does the system work?

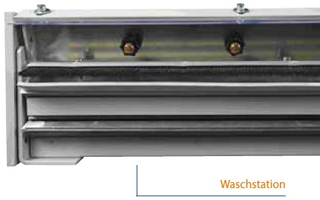

- Using the special nozzles, a metered soap-water mixture is sprayed onto the printing plates

- The special nozzles eliminate the possibility of water dripping after the spray cycle

- A stationary cleaning brush is also located underneath the nozzles

- This is a closed-cycle cleaning process, with rubber seals, to ensure that any water and the waste water are contained.

- A vacuum chamber between brush and the seal evacuates the waste water. Each unit has a separate vacuum pump

- Integrated drying units dry the printing plates after the cleaning process

- The ACS is integrated with the print machine process control system, allowing the information regarding decks used and board widths to be preset automatically in the operator software menu. The operator can readjust individual parameters for each deck

- The operator can set additionally individual for each unit the widths

- The water and soap is automatically mixed by the unique integrated metering unit that is also included