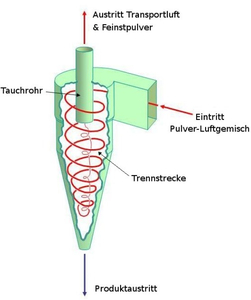

// Centrifugal Dust Collector (Cyclone)

Our Centrifugal Dust Collector, sometimes called a cyclone, a cyclone separator, cyclone filter or cyclone dust collector, can be used on printing machines for the removal of paper and dust particulates from the airstream coming from different components of the machine.

A centrifugal dust separator essentially consists of four parts: the in-feed cylinder (above), cone (middle), the particle collection container (below) and the dip tube which is centrally mounted in the in-feed cylinder.

A high speed rotating air flow is established within the conical container called the cyclone. The air flows in a helical pattern, beginning at the top (wide end) of the cyclone and ending at the bottom (narrow) end before exiting the cyclone in a straight stream up through the center of the cyclone and out the top. This tapering of the cone causes the rotational speed of the air to increase to such an extent that most of the contained paper and dust particles are thrown by centrifugal force against the cone walls. As they decelerate, they separate from the airflow and trickle down into the collection container.

The main advantage of a centrifugal dust separator, since filter cartridges or filter mats are not used, is that maintenance becomes a non-issue while ensuring that its performance is always optimal. The sizing of a centrifugal dust separator is determined by the air volume to be treated. Higher air volumes result in greater separation or lower cut-points (ie lower particle size).

Duo-Technik engineers Centrifugal Dust Collectors for different air volumes to maximize efficiency with low particle cut-points.