CLEAN|CLICHÉ

// Save time and money

The cleaning of printing plates during your production process wastes a lot of time.

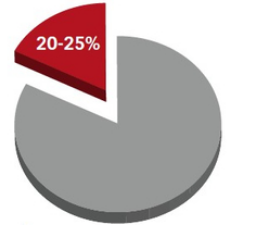

We asked some of our customers who didn’t have an automatic plate cleaning system to estimate how much of time they lose for washing plates, each year.They answered that: 20-25% of the effective machine production time is wasted for cleaning. To put that number into context: A print facility with a 2 shift operation of 3000 hr./year would need 600–750 hours/year just for plate cleaning. That’s time that the printing machine is not productive.

// Why do I need to clean so often?

There are 3 fundamental situations when plate cleaning is usually necessary:

- Cleaning after job set up due to ink drying on the plates during the approval process wait-time

- Interim cleaning after 3000-4000 sheets due to dust or dry ink defects

- Cleaning after the end of the job

Duo-Technik’s QPC is a machine-integrated system that cleans dry ink and dust defects from the print plates without stopping the machine. This quick cleaning process, during printing, takes about 2 minutes with only about 8-10 waste boards. However, final cleaning is not possible.

// What is it used for?

Cleaning of specific dust-related defects on the printing plates – can be used at the discretion of the operator during production

- Increases quality output while reducing the machine down-time required for cleaning

Continuous (automatic, cyclic) cleaning of the printing plates during production

- Particularly recommended for “process” jobs, to improve overall job quality while reducing down-time of the machine required for cleaning of dried ink on the plates.

Quick plate cleaning during a sheet feeder stop

- Faster startup of the machine after press jam up or feeder stop. Down-time for cleaning is reduced to a minimum; creating only 8-10 waste boards.

// How does it work?

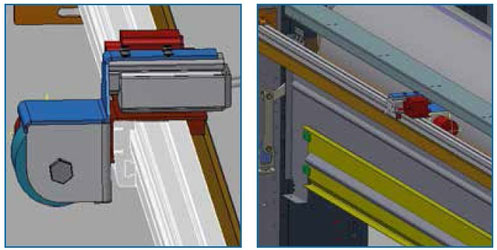

The system consists of a moveable clea-ning head with a unique rotating sponge. The cleaning head travels along the prin-ting cylinder, removing dust and dried ink. The sponge head distance to the printing cylinder can be set through the touch panel in micrometers (0.1mm). After cleaning the printing plates, the cleaning head returns to the integrated docking station where the sponge is clea-ned waiting for the next cleaning cycle.

// What are its unique features?

// What are its unique features?

The cleaning head is cleaned inside the printing machine

- resulting in a long lifetime of the cleaning head and sponge and reduced replacement costs.

- Not only does the cleaning head and sponge last longer their replacement costs are lower than competitive type products.

The cleaning head is automatically set to the printing plate thickness

- Shorter set up times necessary for job set-up.Optionally, the Duo-Technik Final Cleaning Station (FCS) can also be added.

The cleaning head can also be cleaned outside the machine

- Lower replacement spare part costs

//Optionally, the Duo-Technik Final Cleaning Station (FCS) can also be added!

ACS

Duo-Technik’s ACS is also a machine integrated system which is able to make interim plate cleaning which takes only 6 minutes and a effective final plate deep cleaning that takes only two minutes. The printing machine has to be stopped during the cleaning process.

// What is the system used for?

The goal of the ACS system is not only to remove dust spots or dry ink but to deep clean the printing plates. This is especially recommended for long inline production runs. However the printing machine has to be stopped to do the cleaning. This is an interesting feature, since based on the actual ink condition, more or less ink will dry and accumulate on the printing plates and this is really difficult to remove with an in-production cleaning system.

Was sie erhalten:

- In-depth cleaning of all printing plates in 6 minutes

- The 3rd sheet after cleaning is commercial quality

- Quick final cleaning of wet printing plates in two minutes

- Final cleaning of the printing plates can take place during the set-up of a new job

- Metered make-up and controlled usage of soap for the cleaning cycle

- Printing plates are maintained in optimal condition

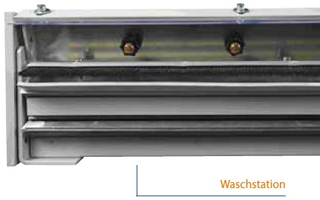

// How does the system work?

- Using the special nozzles, a metered soap-water mixture is sprayed onto the printing plates

- The special nozzles eliminate the possibility of water dripping after the spray cycle

- A stationary cleaning brush is also located underneath the nozzles

- This is a closed-cycle cleaning process, with rubber seals, to ensure that any water and the waste water are contained.

- A vacuum chamber between brush and the seal evacuates the waste water. Each unit has a separate vacuum pump

- Integrated drying units dry the printing plates after the cleaning process

- The ACS is integrated with the print machine process control system, allowing the information regarding decks used and board widths to be preset automatically in the operator software menu. The operator can readjust individual parameters for each deck

- The operator can set additionally individual for each unit the widths

- The water and soap is automatically mixed by the unique integrated metering unit that is also included

With the Final Plate Cleaner you can optimise your plate cleaning outside the press. Whether decentralised at each press or centralised for all presses, Duo-Technik offers all sizes from 1600 mm width to 3600 mm width. Special sizes are also available on request.

// Why a Final Plate Cleaner?

Starting Position:

- The operator clean the cliché next to the printing machine by hand

- or there is a manual central cleaning station for cliché in the factory

- The clichés are cleaned with hand brushes, water and soap (no defined cleaning, no defined application of water and soap, the clichés can be damaged by mechanical cleaning)

Advantages of a central usage of a FPC:

- Parallel cleaning of up to 4 clichés. This saves personnel costs.

- Defined cleaning and defined consumptions.

- Longer life time of clichés thanks to contactless cleaning.

Advantages of a decentral usage of a FPC:

- The operator has more time to control the production.

- Defined cleaning and defined consumption.

- Longer life time of clichés thanks to contactless cleaning.

Manual Cleaning, Central usage

500 Clichés per month, 6.000 clichés per year

5 minutes for manual cleaning

= 500 h cleaning per year

= 500 h * 40 EUR/h = 20.000 Euro

FPC Cleaning, Central Usage

500 Clichés per month, 6.000 clichés per year

1,5 minutes manual cleaning

= 150 h cleaning per year

= 150 h * 30 EUR/h = 4.500 Euro

(depreciation 30 TEUR/5 Jahren)

= 150 h * 40 EUR/h = 6.000 Euro

(personnel cost)

► 9.500 Euro savings per year

The Fluid Dosage System (FDS) consists of 2 combinable modular units:

- FDS-Mix - Automatic premixing of a soap / water mixture for direct consumption or in a storage container

- FDS-Pump - Automatic pumping of a premixed soap / water mixture into the cleaning circuit of the printing machine. The unit is connected to the printing machine and automatically feeds the soap / water mixture to the printing machine with the required line pressure as required.

//FDS- Mix Direct

Das FDS – Mix Direct serves as a mixing station for the manual removal of a soap / water mixture at various points in the company, e.g. Cliché washing area at the printing press. In this way, defined purchase quantities can be regulated by production management and the safety of employees when working with substances with a high pH value can be ensured.

The unit consists of:

- Pressure-operated proportional dosing pump 5-25% (other dosing ranges on request), max. 500 l / h manual setting on a mounting plate, water connection: ¾ “, max. 6 bar

- Suction hose with filter basket for the connection to the tank of the soap concentrate

- Manual shut-off valve in front of the dosing pump input

- Manual shut-off valve after the dosing pump to take off the mixture

// FDS- Mix Storage

Das FDS – Mix Storage has a storage container and is therefore suitable for an automatic, changing volume of the soap / water mixture. Manual removal of the mixture is also possible.

The unit consists of:

- 1 cabinet 600 x 1200 x 400 mm including frame, total height 1800 mm

Integrated in the cabinet:

- 1 suction hose with filter basket for the connection to the tank of the soap concentrate

- 1 pressure-operated proportional dosing pump 5-25% (other dosing ranges on request), max. 500 l / h manual setting on a mounting plate, water connection: ¾ “, max. 6 bar

- 1 mixing tank with automatic level control with a capacity of 30 or 50 l (depending on the number of connected tapping points)

- 1 manual shut-off valve in front of the dosing pump input

- 1 manual shut-off valve after the dosing pump to take off the mixture

// FDS- Pump

The FDS - Pump can be used in connection with an FDS - Mix Storage or with a soap / water mixture provided by the customer.

The soap / water mixture can be sucked in from a container or made available via a line with a maximum of 6 bar.

The unit consists of:

1 cabinet 600 x 600 x 210 mm including frame, total height 1800 mm

Integrated in the cabinet:

- 1 pump per prinping factory: Adjustable, pneumatic double diaphragm pump, installed after the mixing tank to convey the mixture to the tapping points

- 1 manometer per printing factory: Manometer for monitoring the outlet pressure for injection into the cleaning room

- 1 PLC to control the injection valves and diaphragm pumps

- 1 fault indicator light

- 1 electrical connection to the machine interface (machine dependent)

Maximum distance to the acceptance point in the standard: 25 m

Standard design for each delivery point:

- 1 stainless steel injection valve ½ "

1 electrical connection to the injection valve 25 m flexible PE hose 14x12 mm

Various small parts for integration into the washing cycle

The system is delivered with the "Declaration for the installation of an incomplete machine in accordance with Directive 2006/42 / EC, Appendix II 1.B".

Delivery limit - not included in delivery:

- Electrical connection: 115-230V AC, 1-phase, 2 A (FDS - Mix Storage, FDS - Pump)

- Air pressure connection: 6 bar (only FDS - Pump)

- Water connection: 3/4 “, pressure 1-6 bar, without pressure fluctuations during operation

**Important note for the use of cleaning agents - compatibility for components / surfaces:

We recommend a cleaner with a pH value not higher than 11, low foaming, not aggressive to materials aluminium, steel, copper, zinc, nickel, polyurethane. If the local water hardness is more than 5 ° dH (German hardness) or 4 ° e (English hardness), we urgently recommend a lime scale - removing additive for the use of the cleaner. If the local water hardness is higher than 14 ° dh (German hardness) or 11 ° e (English hardness), we recommend an adequate decalcifying system. Duo-Technik will be happy to advise you comprehensively.

Several cleaners are rated "good quality". Please contact us for appropriate product names - or send us a test sample of your cleaner for our qualified test purposes and approval.

Duo-Technik has its own, compliant DUOCleaningAgent Ultimate Cliché Cleaner (UCC) with tested compatibility for components / surfaces in its range.

Duo-Technik has been distributing cleaning systems for many years, therefore we recommend the CITOCLYN cleaning systems.

For more information, please click on the following link: CITOcleaner