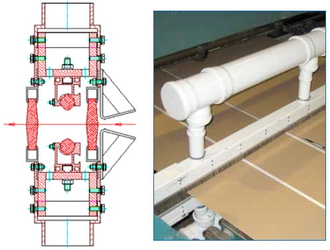

// The dust removal system consists of:

- 2 ionization bars

- 2 vacuum chambers

- 4 brushes

- 2 infeed plates

- 4 pneumatic cylinders to move/adjust the system

- 2 vacuum pumps

- Complete piping

- And an electrical cabinet

The system is integrated in the machine control. At job changes or machine jams, the upper part is raised rapidly to avoid damage to the system or cause machine stoppages. The vacuum levels are set though pump frequency converters based on the board and web thickness.

Our Centrifugal Dust Collector can be added to collect the dust particles

// Depending the available space on the corrugator, the system can be either installed after the slitter or cross-cutter

// How effective is the system?

- Our experience and customer feed-back shows that jobs with full surface printing; the time between press-stoppages for dust-related issues has been extended by two or three-fold or a decrease in down time of 50 - 67 %

- Overall print quality will be increased, leading to a reduction in customer complaints, increased customer satisfaction, and significant lower job costs.

- With less dust floating around, a significant and favorable effect on the overall plant health and safety goals is achieved